Introduction to Logistics Automation

Welcome to the age where robots pick, pack, and ship your goods faster than you can say “Amazon Prime.” In 2025, logistics is no longer just about moving goods from point A to point B—it’s about doing it smarter, faster, and with fewer human errors. And that’s where logistics automation enters the scene.

The Evolution of Logistics

Back in the day, logistics meant warehouses full of workers manually tracking inventory on clipboards. Trucks were routed by guesswork, and customer updates were vague at best. Fast forward to today, and it’s an entirely different story. Digital transformation has taken the wheel.

Why 2025 Is a Turning Point

Why does 2025 matter so much? Because we’ve hit a perfect storm of demand for efficiency, booming e-commerce, labor shortages, and tech maturity. Businesses that embrace automation now will stay competitive—those who don’t might just fade into the background.

What Is Logistics Automation?

Definition and Core Concept

At its core, logistics automation refers to the use of technology to automate the processes involved in the storage and movement of goods. This includes warehouse operations, transportation, inventory management, and even customer communication.

Difference Between Manual and Automated Logistics

Manual logistics relies heavily on human labor and outdated tools. Think spreadsheets, paper checklists, and phone calls. Automated logistics, on the other hand, uses sensors, AI, and software to perform these tasks with minimal human intervention.

Key Components of Logistics Automation

- Automated Guided Vehicles (AGVs)

- Robotic Picking Systems

- Inventory Management Software

- Automated Shipping Labels & Packing

- Data Analytics & Reporting Tools

Technologies Driving Logistics Automation in 2025

Artificial Intelligence (AI) and Machine Learning

AI is the brains behind modern logistics. It can predict demand, optimize routes, and even prevent delivery delays before they happen. Machine learning gets smarter over time, making decisions more accurate as it processes more data.

Internet of Things (IoT)

IoT connects everything—from smart pallets to GPS-enabled trucks. Real-time tracking and condition monitoring (temperature, humidity, etc.) are now the norm, not the exception.

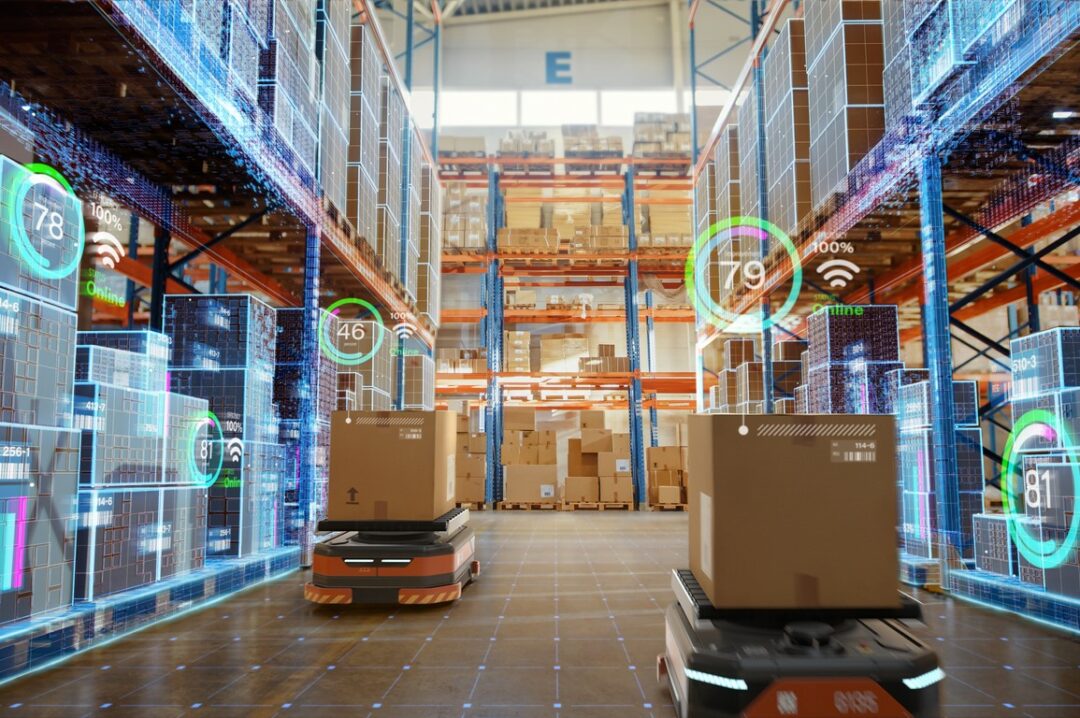

Robotics and Autonomous Vehicles

Imagine robots that never sleep. From warehouse floor robots to self-driving delivery vans, automation has drastically reduced the need for manual labor in repetitive tasks.

Warehouse Management Systems (WMS)

A solid WMS is the command center of a smart warehouse. It streamlines everything from inventory tracking to order fulfillment, ensuring that nothing slips through the cracks.

Cloud Computing and Blockchain

Data accessibility and security are top concerns. Cloud platforms allow global access to logistics data, while blockchain ensures transparency and traceability in the supply chain.

Key Benefits of Logistics Automation

Improved Efficiency and Speed

Automated systems process tasks at lightning speed. What once took hours—like sorting and packing—now takes minutes, boosting overall productivity.

Cost Reduction

Yes, there’s an upfront investment. But over time, automation cuts labor costs, minimizes errors, and reduces wastage, making it incredibly cost-effective.

Enhanced Accuracy and Fewer Errors

Robots don’t get tired or distracted. They pick the right items, route packages correctly, and keep inventory counts precise—every single time.

Better Customer Satisfaction

Faster deliveries and real-time tracking = happier customers. Enough said.

Real-Time Data and Predictive Analytics

With access to real-time dashboards and predictive models, businesses can make smarter, data-driven decisions.

Challenges in Implementing Logistics Automation

High Initial Investment

One of the biggest roadblocks is the cost. Robots and AI don’t come cheap—but think of it as an investment rather than an expense.

Integration with Legacy Systems

Older systems often aren’t compatible with new tech, making integration tricky and time-consuming.

Cybersecurity Risks

As logistics becomes more digitized, it also becomes more vulnerable to cyber threats. Keeping data secure is paramount.

Workforce Adaptation and Training

Employees need to be trained to work alongside automation. It’s not about replacing humans but empowering them to focus on higher-value tasks.

Real-World Applications in 2025

E-commerce Fulfillment Centers

Think about your last online order. There’s a good chance it was packed by a robot and shipped using AI-optimized routing. E-commerce relies heavily on logistics automation to meet customer expectations.

Last-Mile Delivery Optimization

That final leg of delivery is the most expensive and complicated. Automation helps reduce costs and increase reliability through smarter scheduling and real-time updates.

Smart Warehousing and Inventory Management

With robots handling stock movement and sensors updating inventory in real-time, warehouses are becoming intelligent ecosystems.

The Role of Big Data and Analytics

Demand Forecasting

Big data helps predict future demand based on buying patterns, seasonality, and even weather. This ensures businesses stock just the right amount.

Route Optimization

AI-powered tools can calculate the fastest and most fuel-efficient routes, reducing delivery times and transportation costs.

Inventory Predictions

Knowing when you’re going to run out of stock before it happens? That’s the power of predictive analytics.

Environmental and Sustainability Impact

Reduced Carbon Footprint

Efficient routing and electric delivery vehicles significantly cut down on emissions, contributing to greener operations.

Energy-Efficient Operations

Automated systems are designed to use energy wisely—turning off when not in use and optimizing resource usage.

How Small and Medium Enterprises (SMEs) Can Benefit

Accessible Tools and SaaS Platforms

Thanks to Software-as-a-Service models, even small businesses can tap into automation without massive infrastructure investments.

Scalable Automation Options

Start small and scale as needed. SMEs can automate only the parts of their logistics they can afford, and expand over time.

Logistics Automation and Job Transformation

Will Automation Replace Jobs?

It’s a fair concern. But rather than replacing jobs, automation is transforming them. Repetitive tasks are being offloaded, allowing humans to focus on creative and strategic work.

New Roles and Upskilling Opportunities

From robot technicians to data analysts, new roles are emerging. Companies must invest in upskilling their workforce to stay ahead.

What Businesses Should Consider Before Adopting Automation

Cost-Benefit Analysis

Know your numbers. Weigh the investment against potential long-term gains.

Vendor Selection

Choose vendors with proven track records, robust customer support, and scalable solutions.

Employee Training and Change Management

Ensure your team is on board. Change is hard, but with proper communication and training, it’s achievable.

The Future of Logistics Automation Beyond 2025

Hyper-Automation

This goes beyond basic automation. It combines multiple advanced technologies to fully automate end-to-end logistics processes.

Human-AI Collaboration

The future isn’t robots versus humans—it’s robots with humans. The synergy will unlock levels of efficiency we’ve only dreamed of.

Conclusion

So, what is logistics automation and why does it matter in 2025? It’s the key to staying competitive in a fast-paced, tech-driven world. From enhancing efficiency to enabling real-time decision-making and sustainable operations, automation is no longer optional—it’s essential. Businesses that act now are setting themselves up for long-term success, while those who hesitate may find themselves left behind.